Danieli Automation S.p.A.

Via B. Stringher, 4

33042 Buttrio (UD) – Italy

Phone (+39) 0432 518111

Fax (+39) 0432 673177

E-mail info@dca.it

P.IVA 00162990303

OUR MILESTONES:

Danieli Automation continued expanding its steel process knowledge and the ability to control the processes by means of the most modern information technologies.

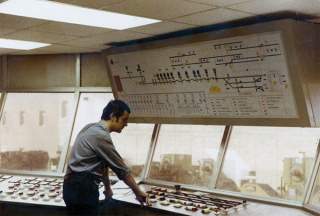

1960 › 1970

1970

The hot metal detectors (HMD) model FIM1 was designed and put into production.

1970

TDR40 timing devices for cut-to-measure of rolled section with flying shears.

1970

Electronic components organized in a modular card system were used for the first mill analogical control system, giving to each stand the speed reference value optimized for a regular rolling flow.

1970 › 1990

1974

Liquid steel level optical detector in the continuous casting mould (patented).

1978

First PLC device with high speed response with a logical instruction set for sequential actions (IPS740) and a device with an analogical instruction set for control applications (IPS440).

1990 › 2000

1992

The first profile gauge was produced for the DDS rolling mill in Denmark and it was suitable for flat sections up to 140mm wide.

2000

Danieli Automation made its debut in the market of industrial anthropomorphic robots.

2000 › 2020

2010

Istand process virtual reality simulation.

2011

3Q Technology – A new approach to process control for a modern plant operation

2013

QDRIVE – Medium voltage and Multilevel drives for top performances and big flexibility

2013

QHEAT – Induction heating system for long and flat products

2016

DIGI&MET: new business unit to develop innovative plant design concepts based on digital innovation to simplify metals complexity

2017

QONE – Efficient energy source for electric furnaces through hi-performance power unit